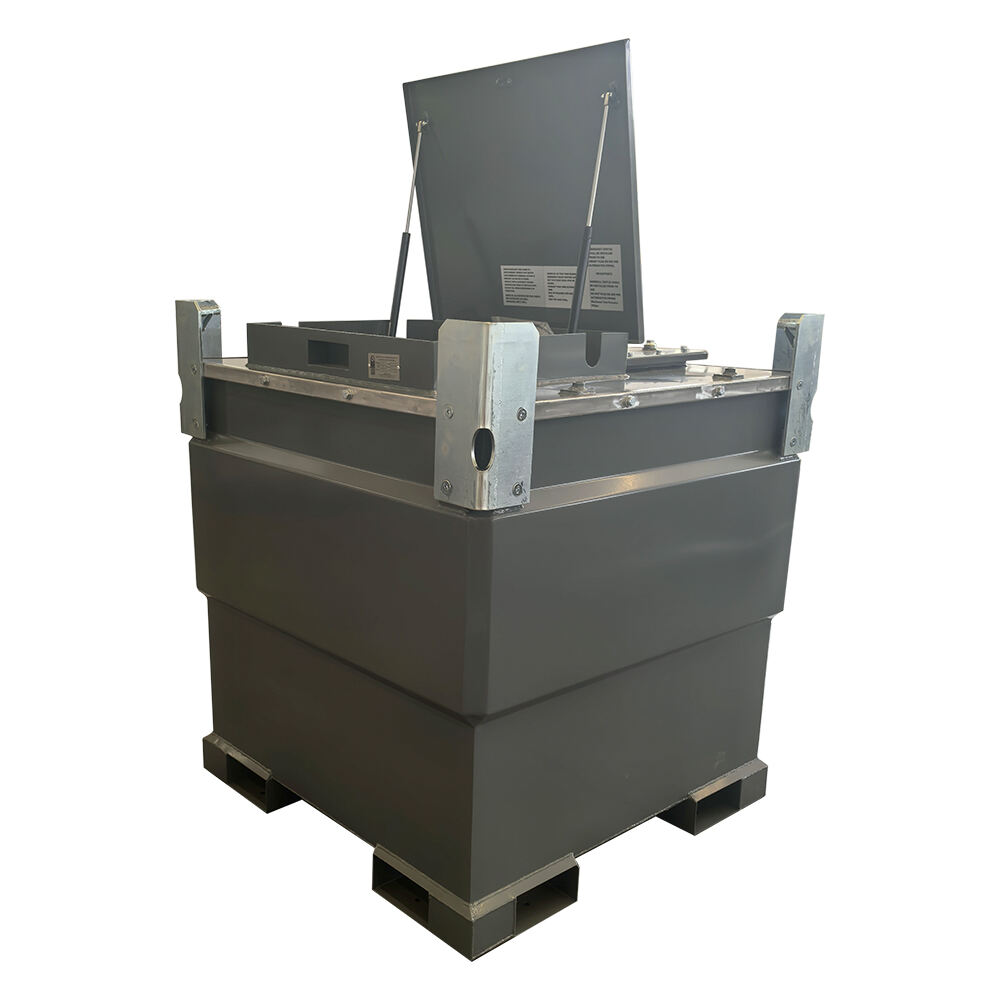

Predaj Transcube Palivového Bako do Španielska

Odolnosť proti vysokým teplám prenosového palivovej nádrže je obvykle dobrá, čo určujú jej materiálne vlastnosti a dizajnové rysy. Nasleduje podrobné predstavenie:

1. Výber materiálu

Prenosné palivové nádrže sú všeobecne vyrobené z inžinierskych plastov odolných voči vysokým teplám alebo kovových ligatúr. Inžinierske plasty, ako je napríklad polyetheretherketon (PEEK), majú vynikajúcu odolnosť voči vysokým teplám a môžu pracovať stabilne dlhý čas v prostredí s teplotami vyššími ako 200 °C. Kovové ligatúry, ako sú hliníkové ligatúry, sú nie len silné, ale majú tiež dobrú tepelnú vodivosť a odolnosť voči vysokým teplám, a dokážu prestať vysoké teploty bez deformácie. Tieto materiály môžu udržiavať štrukturálnu stabilitu v prostredí s vysokými teplami, prevencia prerušenia alebo deformácie nádrže kvôli tepelnej expanzii a kontrakcii, a zabezpečiť bezpečné ukladanie a prepravu paliva.

2. Teplová izolácia

Aby sa ďalej zvýšila odolnosť proti vysokým teplám prenosového palivovej nádrže, je obvykle na vonkajšej strane nádrže umiestnená izolačná vrstva. Izolačná vrstva môže byť vyrobená z tepelne izolujúcich materiálov, ako sú keramické vlákna a sklené vlákna. Tieto materiály majú extrémne nízku tepelnú vodivosť a môžu efektívne brániť v prenosu vonkajšieho tepla do vnútra nádrže, čím sa zníži rýchlosť stúpania teploty paliva v nádrži. Okrem toho niektoré prenosové palivové nádrže budú tiež navrhnuté s tepelnými odvodňovacími štruktúrami, ako sú chladicí lišty alebo chladicí kanály, aby sa zvýšila plocha na odvádzanie tepla a akcelerovala sa jeho odvodenie, takže sa palivová nádrž vie udržať na nižšej teplote vysoko-teplom prostredí.

3. Návrh bezpečnostnej rezervy

Počas procesu návrhu prenosnej palivovej nádoby sa bude zohľadniť určitá bezpečnostná marha, aby sa zabezpečilo, že bude stále normálne fungovať v extrémne vysokotemperatúrnych podmienkach. Napríklad, odolnosť nádoby pred tlakom bude navrhnutá vyššie ako bežný pracovný tlak, aby sa zabránilo tomu, aby sa vnútorný tlak nádoby stal príliš vysoký kvôli rozšíreniu paliva kvôli vysokému teplu. Zároveň sa bude aj striktne testovať uzátvorkovacia vlastnosť nádoby, aby sa zabezpečilo, že nebude dochádzať k úniku paliva v vysokoteplotnom prostredí.

https://www.sumachine.com/

Odporúčané produkty

Horúce novinky

-

Dvojitostenný prenosný dizelový benzinový kubický tank s čerpadlom na predaj pre Maurícius

2024-11-11

-

Prepravná nádrž na palivo s dvojitou stenou Prebiehajúci odovzdanie do Španielska

2024-11-07

-

Preprava prenosnej leteckej palivovej nádoby s pumpy

2024-10-12

-

Kubická nádrž na ropa z uhlíkového ocele pre USA

2024-11-14

-

Kubická nádrž s pumpy z uhlíkového ocele

2024-11-13

-

Stacionárna dvojitostenná nádrž na dieselové palivo na predaj do Španielska

2024-11-06

-

predaj prenosnej palivovej nádrže kapacity 251 až 552 galónov pre USA

2024-11-05

-

predaj prenosnej palivovej nádrže kapacity 251-2000 galónov pre Grenadu

2024-11-01

-

predaj prenosnej palivovej čerpadla s nádržou kapacity 552 galónov pre USA

2024-10-30

-

Prenosná palivová nádrž s pumpy na predaj do Španielska

2024-10-22

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

IS

IS

KA

KA

HT

HT

KK

KK

UZ

UZ