Above ground tanks are special containers which are kept on the top of ground. Liquid Tanks are extremely helpful as they come in different designs that can be used to retain a variety of fluids, including water, oil, and chemicals. They have their pros and cons so lets understand both of them. This article will discuss above ground gasoline tank, their function and how to properly design, install, and maintain them.

But before we get into the pros and cons of above ground tanks, let’s first talk about the basics. Above ground tanks are made of various materials, such as reinforced concrete, corrosion-resistant steel or Polymer plastic. These tanks are designed to contain various liquids that may also be toxic if not stored properly. This means that there is caution in how we utilize them. Types of Above ground tanks are many and varied. Some tanks are tall and narrow; some are wide and flat; some are rectangular. A tank can either be big or small depending on the volumn of the liquid that you need to store, and it depends on the use of tank as well.

Above ground tanks are extremely easy to access which is one of their biggest advantages. Because these tanks are placed over ground level, it is much easier for the workers to inspect them or carry out maintenance or repairs. Moreover, this is crucial; regular checks help prevent glitches. Aboveground tanks are also less expensive to install than underground tanks. However, it does have some drawbacks as well. One limitation being that above ground fuel tank are susceptible to weather, such as strong winds and heavy downpours. Since these tanks are kept outdoors, if they are not well maintained, they are more likely to be damaged or leak.

If you are considering the installation of an above ground tank, there are a few key factors that you should take into account. Starting with the basics, then figure out how much liquid you need to store and what kind of liquid will it be. There are many different types of tanks needed for different liquids. The next thing to do is to select a durable tank material that will last under harsh weather conditions. For instance, some materials resist rust and corrosion better than others. Equally important to installation is making sure that the tank is sitting on a flat, level surface. This keeps the tank stable and minimizes the likelihood of leaks occurring. After the tank is set up, it needs to be connected to a pump or other equipment. This apparatus is to economically and safely transact the liquid in and out of the tank.

Caring for your above ground tank and inspecting it regularly is crucial to keeping it safe and functional. For a proper maintenance of the tank, you need to run through some checks regularly. Regularly cleaning the tank, for instance, can help stop dirt and sediment from accumulating inside your tank. Confirm that there are no leaks or damage to the tank. If you see anything wrong, it needs to be repaired immediately to prevent larger problems. Also, it is important that you check the tank for any signs of wear and tear, such as rust or cracks. Regular maintenance according to the manufacturer's recommendations will help keep it operating well for years to come.

This is the key question you should address when building your above ground tank project, you will make sure to choose the materials that will make the process safe and efficient for the coming future. Typically these tanks are made of steel, concrete and plastics. Steel tanks are large and robust, but they need to be treated to protect against rust. Concrete tanks are also able to store large quantities of liquids, but they can be very costly to install or impossible to repair, in case of damage. Plastic tanks are common because they are light, will not rust and are generally less expensive. The right material is a health guarantee for your tank for many years.

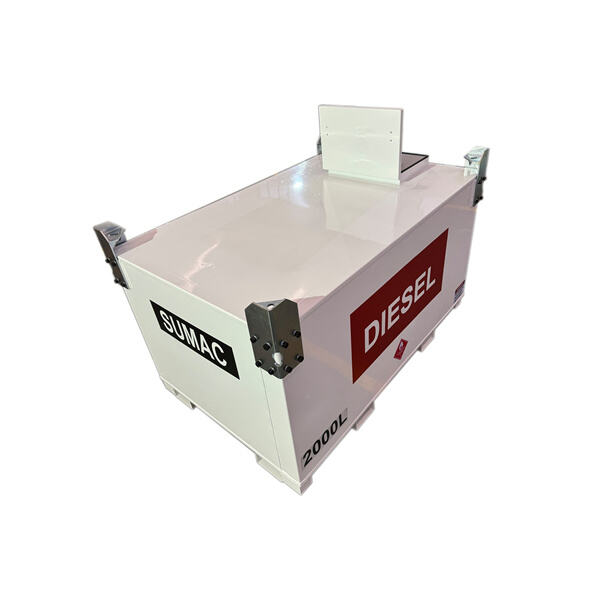

SUMAC recyclers and ELV equipment solve environmental issues and recycle the materials that are discarded to make them valuable. The recycled rubber, metal and other materials could be repurposed into a variety of industrial fields. The above ground tanks, portable fuel tank cube is designed to deliver fuel precisely where and when you require it.

SUMAC tire recycling machines and ELV recycling equipment have CE certifications. CE certificate indicates our machines satisfy the basic health safety, above ground tanks, and protection requirements set by the European Union. This permits the machines to be sold and utilized on the European market. It also acts as an indication of the quality and compliance with international standards.Regarding NW-1000, NW-2000, and NW-4000 cube tanks we are able to provide a UL certificate. The UL (Underwriters Laboratories) certification is a prestigious mark across the United States and many other nations. It is a confirmation the fact that our tanks were rigorously tested and meet the standards of safety and performance stipulated by UL. This certification is important for ensuring the safety and security of tanks, particularly when they are used for storage or transportation of potentially hazardous materials.

SUMAC Auto Recycling Equipment Co., Ltd. (SUMAC) is an incredibly Chinese-owned and operated company. It above ground tanks and sells Automatic Waste Tire Recycling Machines.

Sumac above ground tanks innovative technology and showcases the most recent equipment and solutions for construction While doing so you can see the strength of Sumac's global construction machinery brand gain an understanding of how the industry is evolving and sector demonstrate the strength of industrialization and determination to attain sustainable development